More than 50,000 tons per year of PET, PS, and HDPE plastic waste sent for recycling, generating new secondary raw material ready to be reintroduced into the production supply chain.

Evolution: a supply chain project for plastic recycling

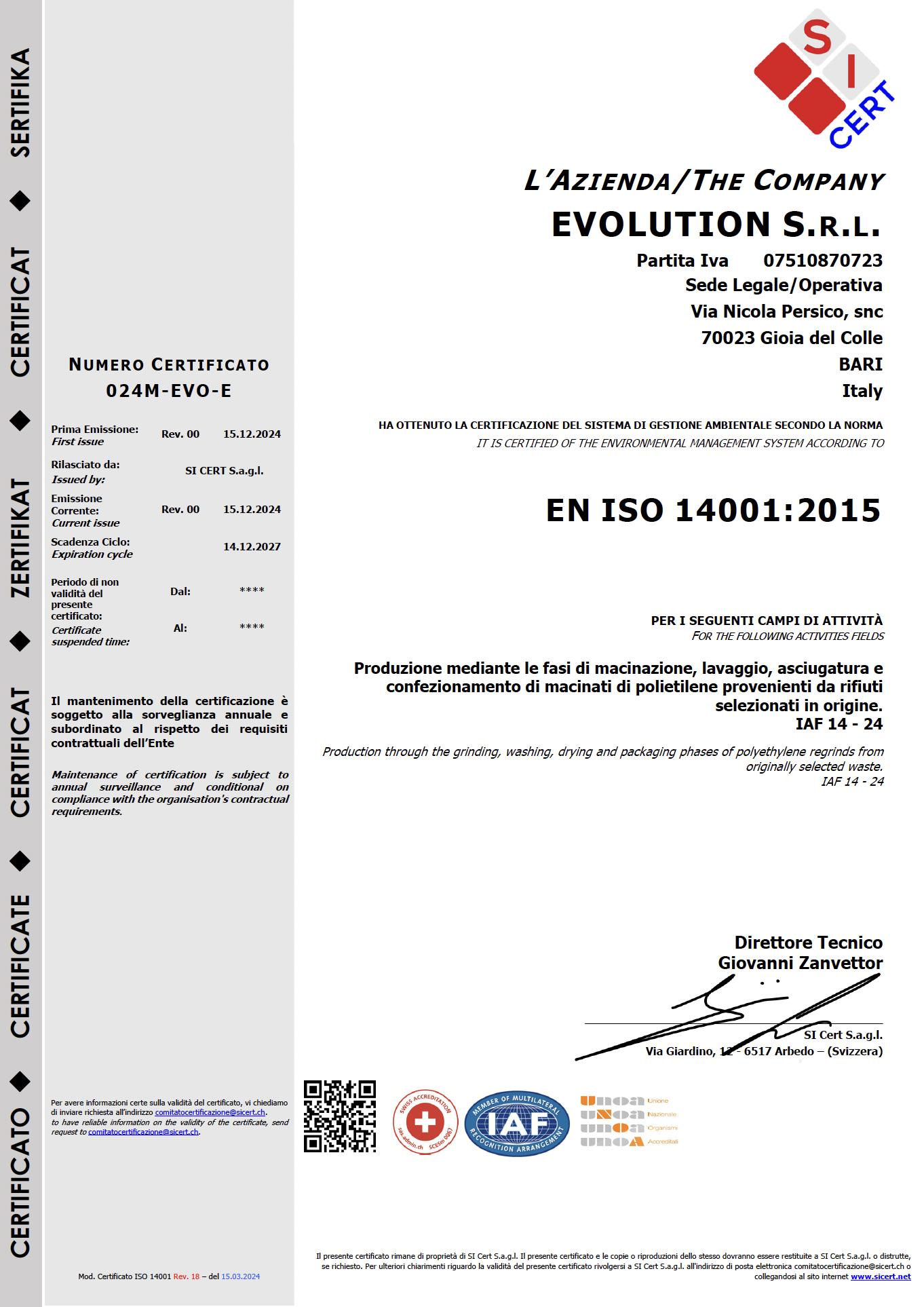

Evolution was founded in 2014 on the initiative of Forever Plast, which launched the first production line dedicated to creating secondary raw materials in HDPE (high-density polyethylene), through a process of washing and mechanical recycling of post-consumer plastic waste from urban sources.

In 2022, the project expanded with the entry of Gruppo Happy and Gruppo Serioplast, aiming to build an integrated recycling supply chain. This new structure includes:

- The upgrade of the existing washing line for polyethylene waste treatment.

- The creation of a new production line for washing and processing two additional polymers:

– PET (polyethylene terephthalate)

– PS (polystyrene)

The initiative fits within a context of growing focus on the circular economy, with the ambition to give new life to plastic waste through sustainable and innovative technologies.

JOINT VENTURE PARTNER

It is a leading company in the production and marketing of HDPE, PP, and PS granules, also obtained from the regeneration of plastic materials collected through separate waste collection. It stands out as the only company in Italy able of industrially recycling PS, thanks to its specialized know-how.

It is one of the leading European players, specialized in the production and marketing of plastic and cellulose packaging solutions for fresh and preserved foods, fully capable of meeting the diverse packaging needs of the food industry and large-scale retail sector.

A global leader in the production of rigid plastic packaging, bottles, containers, and caps for the consumer goods market, it has placed quality and sustainability at the core of its strategy since the 1970s. Through Centro Plastica Srl, it produces rHDPE from post-consumer waste, strengthening its commitment to the circular economy.

The numbers of recycling

Input:

- 20.500 PET

- 11.000 PS

- 18.500 HDPE

Gen

Feb

Mar

Apr

May

Jun

Jul

Ago

Sep

Oct

Nov

Dic

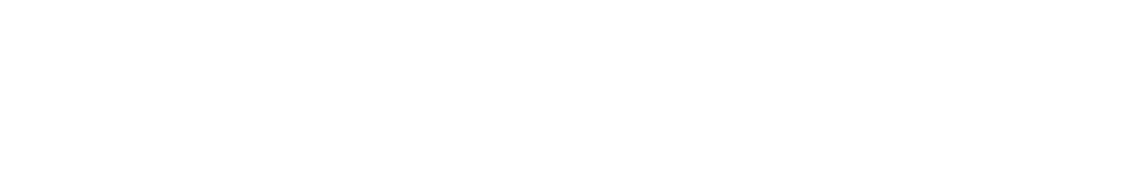

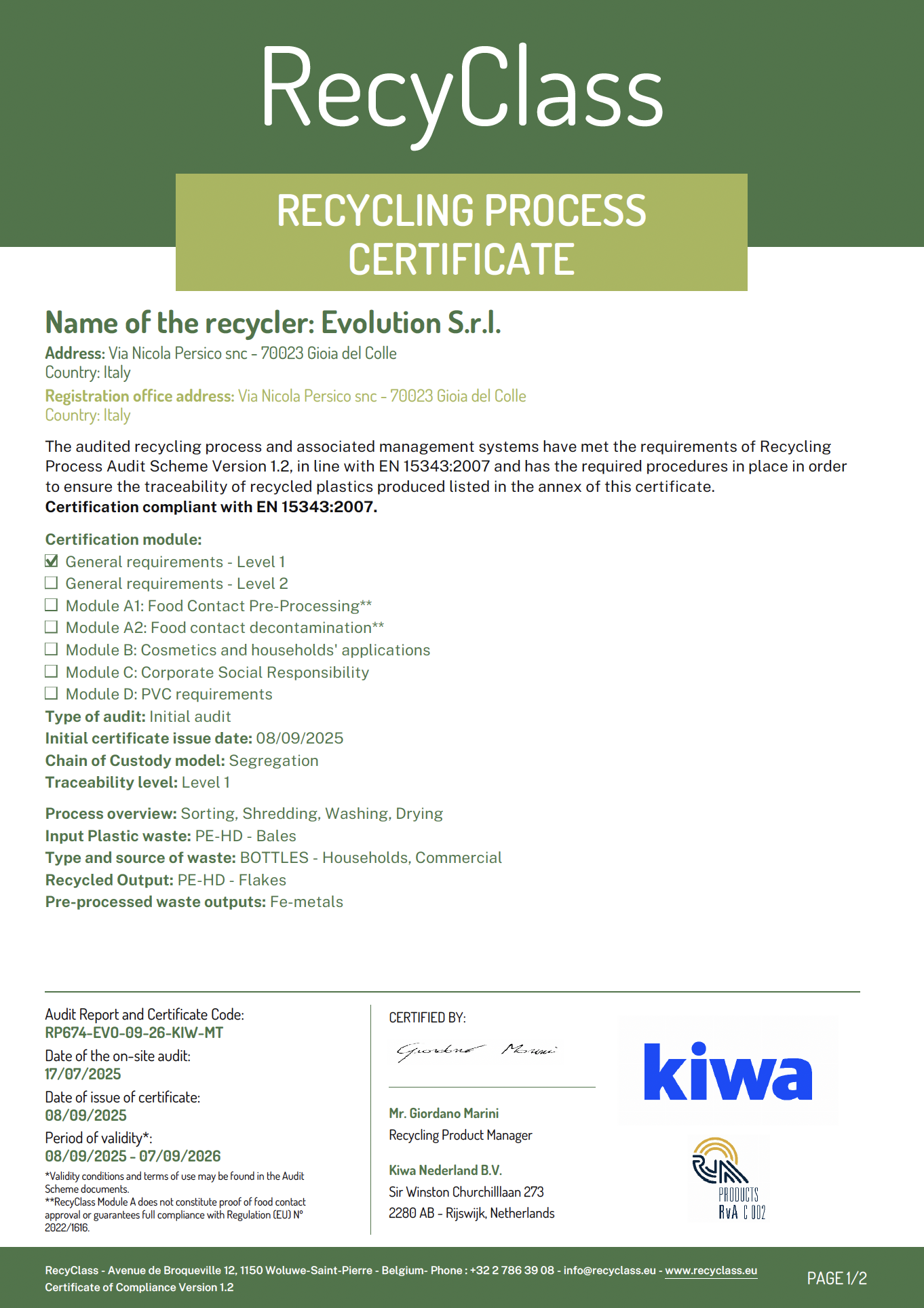

THE HDPE RECYCLING PROCESS

Within Evolution, the line dedicated to HDPE (high-density polyethylene) recycling starts with selected bottles and packaging sourced from the post-consumer plastic recovery chain. Through a mechanical recycling process involving grinding, washing, and drying, the material is transformed into high-quality recycled flakes.

These flakes represent an ideal secondary raw material for the production of new bottles, mainly for the home care and personal care sectors, thus making a tangible contribution to closing the plastic packaging loop.

01

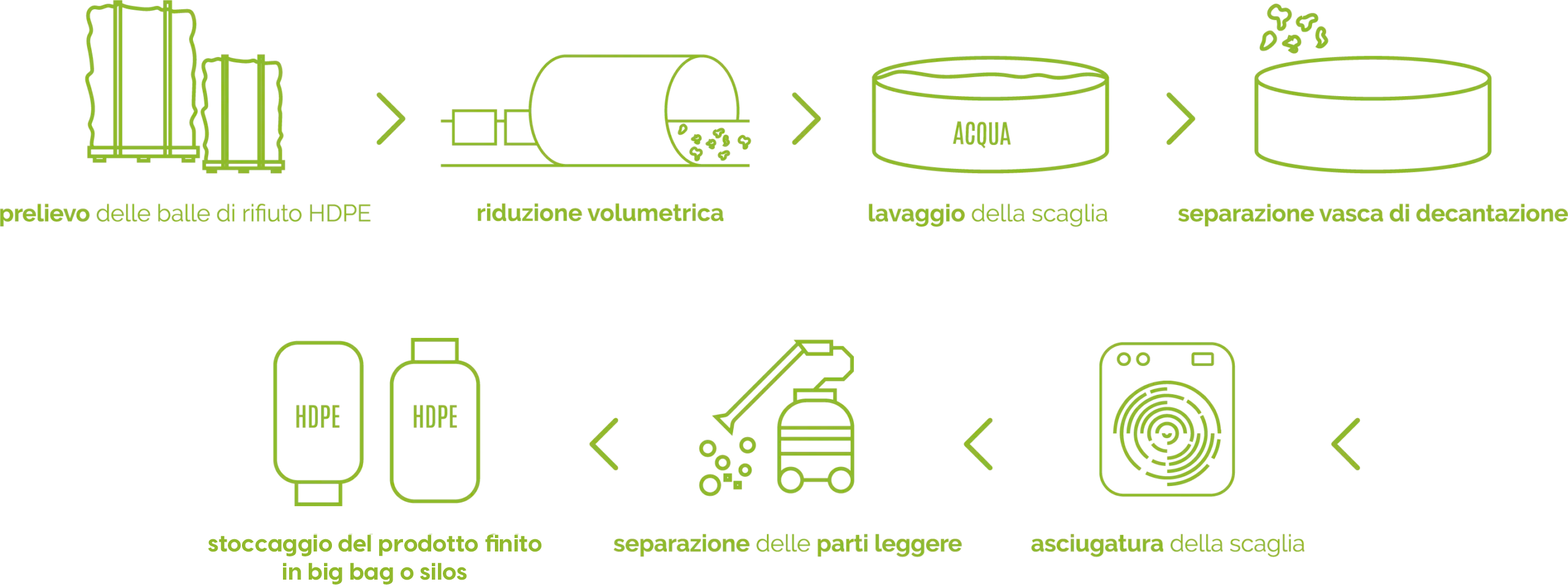

THE PET RECYCLING PROCESS

Thanks to a state-of-the-art PET washing line, equipped with integrated sections for sorting, hot washing, and drying, Evolution can produce high-quality flakes suitable for food-grade applications.

The line is equipped with metal and polymer contaminant separation systems, strategically positioned both upstream and downstream of the washing process. These devices ensure a high level of material purity, in full compliance with the quality standards required for food-grade recycling.

By mid-2026, the installation of an EFSA-approved decontamination line is planned. This system is designed to produce R-PET pellets suitable for direct food contact. The new line will make it possible to obtain food-grade material without the need for functional barriers, allowing it to be directly used by food packaging manufacturers in accordance with current regulations.

02

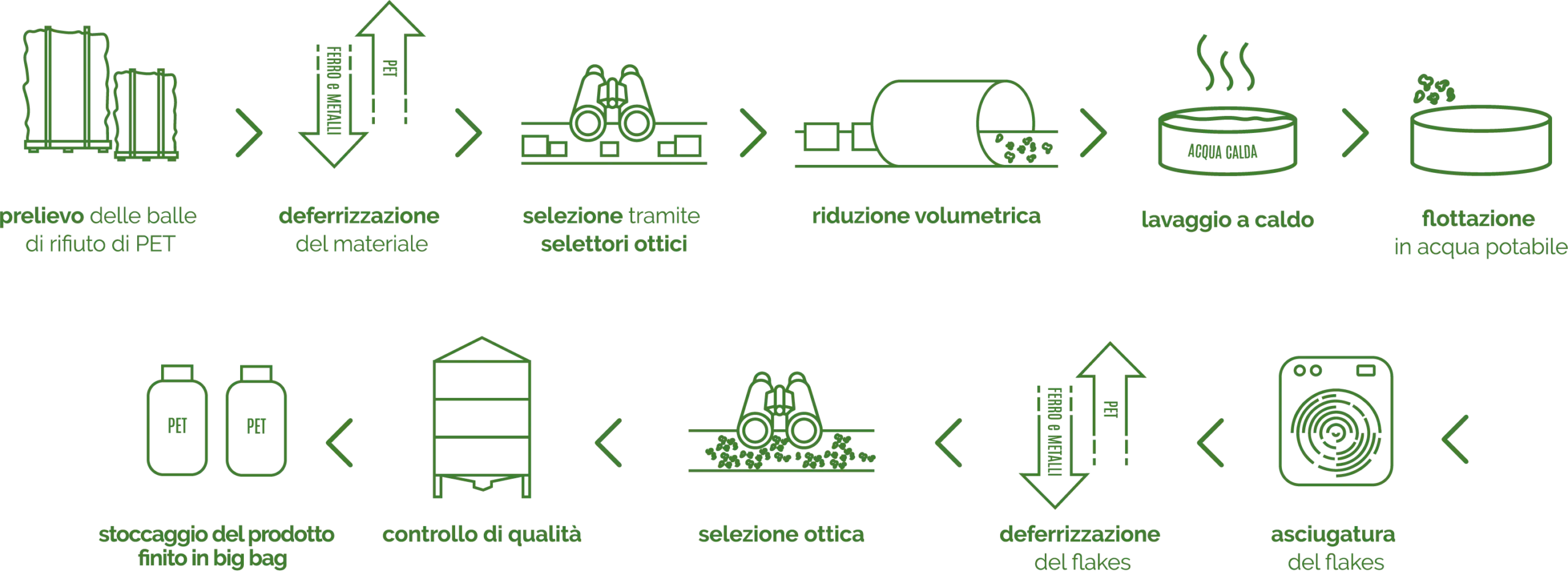

THE PS/XPS RECYCLING PROCESS

The line dedicated to the recycling of polystyrene (PS) packaging from post-consumer collection represents a strategic system within the company’s production process. It is currently one of the few operational lines in Italy able to produce high-purity washed PS flakes, compliant with the standards required for food-contact applications.

The flakes are then subjected to a specialized decontamination step to create food-grade pellets, fully compliant with current regulations. This stage is carried out by Forever Plast using the proprietary Newer technology, developed and patented by Eni Versalis.

03

Our products

Clear transparent flakes

Clear

COMING SOON

Light Blue transparent flakes

COMING SOON

EFSA approved PET granules

coming soon

HDPE floral flake

HDPE floral flake

coming soon

Our products

Work with us

WE GIVE PLASTIC A SECOND LIFE, TRANSFORMING WASTE INTO A SUSTAINABLE INVESTMENT FOR THE FUTURE.

Contact us to find out more about our company.

WE GIVE PLASTIC A SECOND LIFE, TRANSFORMING WASTE INTO A SUSTAINABLE INVESTMENT FOR THE FUTURE.

Contact us to find out more about our company.

Evolution S.r.l.

Via Nicola Persico snc – 70023 Gioia del Colle (BA)

C.F. e P. IVA IT0751087072